News

TreeWater, a miracle treatment for polluted water

TreeWater, a miracle treatment for polluted water

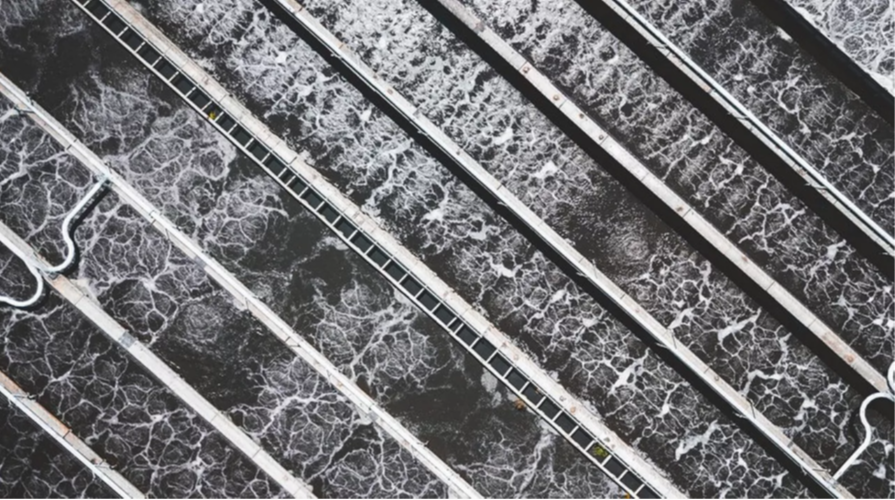

Its advanced oxidation process proves formidable against pollutants, while being less expensive and more environmentally friendly than other filter systems. Above all, it can pave the way for wastewater reuse, particularly in industry.

When it comes to water pollution, further research and knowledge very rarely leads to good news. A simple formula sums up the situation perfectly: the more you look, the more you find. By broadening the spectrum of pesticide residues studied, the Agence nationale de sécurité sanitaire, de l'alimentation, de l'environnement et du travail (Anses) has discovered that 11.5 million French people drank non-compliant water at least once in 2021, three times as many as in 2020. And what can we say about the recent discovery, in this most precious of resources, of PFAS, the perfluorinated compounds massively used in industry, harmful to health and so resilient that they have been dubbed "eternal pollutants"?

And yet, the more polluted water is, particularly with pesticides, the more difficult it is to treat and reuse, at a time when shortages are set to increase by 50% by the end of the decade, according to the European Commission. Conventional wastewater treatment plants have difficulty treating all these micropollutants," says Marc-Emmanuel Bouchard, former director of the water treatment division at Comap. We need to develop technologies to destroy these harmful elements.

Today's most effective processes for treating micropollutants - activated carbon filters or reverse osmosis membranes - have the main drawback of blocking and storing pollutants, not eliminating them. They must therefore undergo special treatment, such as incineration, and the membranes are often cleaned with chemical products. Not to mention that, in the case of reverse osmosis, the operation consumes an enormous amount of energy. Not exactly an ecological panacea. Fortunately, a promising new alternative seems to be emerging for water treatment.

Hydrogen peroxide + UV lamp = advanced oxidation

It was within the Comap group that Marc-Emmanuel Bouchard met Bruno Cédat, a doctoral engineer in charge of deploying the advanced oxidation technology to which he had devoted his thesis. "The results were very encouraging, but a restructuring of the company brought the project to a halt", regrets Marc-Emmanuel Bouchard. Convinced they were on to something, the two men left the group to pursue their research into advanced oxidation. In 2017, they founded TreeWater to commercialize the technology.

At first glance, the technology seems simple. The company has developed a reactor, through which the water to be treated passes, combining two elements: UV lamps, already well known for their use in water disinfection, and hydrogen peroxide, better known as hydrogen peroxide. In addition to their purifying function, the lamps' rays also transform hydrogen peroxide into hydroxyl radicals, a highly reactive oxidant that attacks all organic molecules passing within range. The operation is therefore extremely effective in destroying a wide range of pollutants: detergents, pesticides, viruses, bacteria, even microplastics. "Depending on the pollutants being treated, we need to adjust the parameters between the irradiation dose of the lamps and the quantity of hydrogen peroxide used", explains Marc-Emmanuel Bouchard.

Metals, on the other hand, escape its power. However, if the water stream to be treated contains metals, the TreeWater reactor can be combined with other conventional filters effective in treating inorganic pollution, such as reverse osmosis or activated carbon. With this technology, the company is initially targeting industry, a major user of water and source of pollution. At a later stage, the process could be installed in wastewater treatment plants or even used to purify certain water tables.

Towards water recycling in industry

The technology has attracted the interest of a number of manufacturers in sectors as varied as paper, textiles, chemicals and pharmaceuticals, and has already been deployed at over a dozen sites. The major advantage of our process is that it destroys pollutants, not just stores them," says Marc-Emmanuel Bouchard.

What's more, it uses very few chemicals and presents no danger to the environment. Hydrogen peroxide is largely consumed during the operation, and what's left of it has a very short shelf life."

More importantly, advanced oxidation offers significant savings in terms of both money and energy. Depending on the nature of the pollutants, the level of contamination and the size of the water flow to be treated, the process can consume two to three times less energy than reverse osmosis. Similarly, it can be half as expensive for a small flow, with savings climbing exponentially with the size of the project. This is an attractive proposition for manufacturers, especially as the reactor takes up less space than conventional filtration processes.

Last but not least, the technology paves the way for water recycling in industry. Once the resource has been treated, the industrialist can reuse it without risk for machine cleaning or even as an ingredient, so effective is advanced oxidation on pollutants.

Theoretically, we could even make the water 100% pure, but that would be more expensive," says TreeWater's CEO. We treat it according to the needs of the manufacturer. However, in France, raw water costs around 3.50 euros per cubic metre, compared with around 6 euros for recycled water, which doesn't encourage recycling. We need a political decision to change this. But the price is still more attractive than the cost of incinerating pollutants, estimated at between 50 and 400 euros per cubic metre.

Laundry and disruptive technologies

In any case, the company is multiplying its initiatives. A winner of the EU-funded Life Recyclo project, it has been awarded 1.5 million euros to test its technology in three laundries in France, Luxembourg and Spain, with the aim of limiting both water consumption and pollutant emissions. The prototype, recently installed in the Spanish laundry, will enable the resource to be reused to the extent of 50% to 80% of requirements - a promise at a time when Europe's 11,000 laundries consume 42 million cubic meters of water every year.

But here again, regulations in France don't seem to be up to the challenge. "A decree still prohibits the reuse of wastewater for products in contact with the skin", sighs Marc-Emmanuel Bouchard. This may explain the country's poor recycling results. According to Water Reuse Europe, the rate of wastewater reuse in 2020 was 8% in Italy, 14% in Spain and... 1% in France. Compare this with Israel, which recycles 87% of its wastewater!

Pending legislative changes, TreeWater is continuing its research into advanced oxidation. With funding from Bpifrance and France Relance, the 15-employee company is developing two projects. The first is aimed at eliminating PFAS by using persulfates as oxidants, thus sounding the death knell for these eternal pollutants.

The second aims to create a breakthrough technology with the development of an electro-oxidation process capable of replacing all existing treatment and filtering systems, at costs 20 to 25 times lower than current electro-oxidation operations. This system, combining advanced oxidation and rotating electrodes, can destroy most pollutants. Called ElectRotate, the technology won a prize in Bpifrance's i-Nov competition. These two projects should lead to commercialization by 2025-2026, reviving hopes for sustainable management of our water resources.

Read Pierre Fortin's article on the Les Echos website.