The Electrotate project

The Electrotate technology

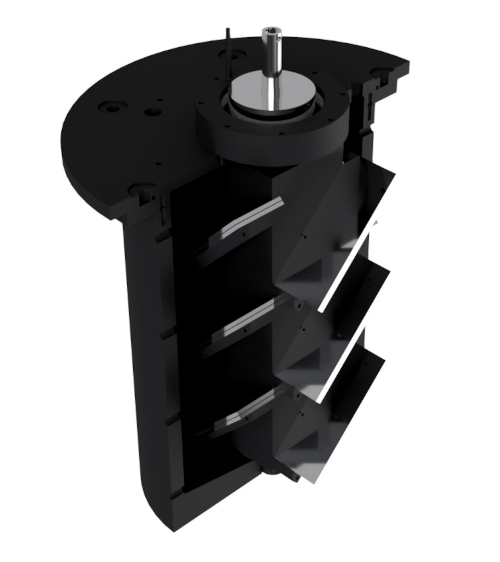

The Electrotate technology has been developed in collaboration with the CNRS to meet these new challenges. The objectives of this process are to reduce energy consumption and the use of chemical products in advanced oxidation processes, to treat or recycle industrial effluents at lower cost, and to extend the efficiency spectrum of advanced oxidation to refractory molecules such as PFOS, metals and microplastics. Electrotate targets all sectors of industry facing effluent treatment/recycling problems, with the ambition of combining cost improvement with a smaller environmental footprint.

This technology takes account of industrial constraints such as

- the compacity of equipment

- the variable quantity and quality of their effluent.

It adapts to the quality of the effluent, since it can combine

- electrocoagulation (particle removal) and

- electro-oxidation (destruction of dissolved pollutants).

Its operation is based on rotating electrodes in which a voltage adapted to the pollution of the effluent is applied.

Electrotate technology represents a technological breakthrough in the effluent treatment and recycling sector. This innovation is currently being developed and will soon be available to manufacturers.

Soutiens/Financements

Labels

Service d’Information

du Gouvernement

Fostering the emergence of future champions in our sectors of excellence.

France 2030, designed in consultation with economic, academic, local and European players, now offers exceptional resources to meet the ecological, demographic, economic, industrial and social challenges of a constantly changing world.

This unprecedented plan for innovation and industry reflects a dual ambition. Firstly, to sustainably transform key sectors of our economy (energy, automotive, aeronautics, digital and space) through innovation and industrial investment. Secondly, to position France not just as a player, but as a leader in the economy of tomorrow.

France 2030 is also innovative in terms of its scope. In total, more than 50 billion euros, including 34 billion euros in new funding, will be invested to ensure that our businesses, universities and research organizations succeed in their transition to strategic sectors.

Bruno Bonnell, General Secretary for Investment, is in charge of overseeing the project. A unified governance structure has also been put in place to ensure effective deployment of the 54 billion euros earmarked.

France 2030 sets 10 objectives based on three challenges: better production, better living and a better understanding of our world.

- Develop small, innovative nuclear reactors in France, with improved waste management.

- Become the leader in green hydrogen.

- Decarbonize our industry.

- Produce nearly 2 million electric and hybrid vehicles.

- Produce the first low-carbon aircraft.

- Invest in healthy, sustainable and traceable food.

- Produce 20 biomedicines to combat cancer and chronic diseases, including age-related illnesses, and create the medical devices of tomorrow.

- Put France back at the forefront of cultural and creative content production.

- Play our full part in the new space adventure.

- Invest in the deep-sea field.

These 10 major objectives are supported by 5 cross-functional levers (raw materials, components, digital technologies, talent and innovation financing), which are essential to achieving this ambition.

So that France remains master of its own destiny, and regains its full independence.

You can access all the open schemes here: link to the "dispositifs de France 2030" search engine.

Useful links :

• Plan overview : https://www.info.gouv.fr/france-2030

• The Twitter account of the Secrétariat général pour l’investissement (SGPI), in charge of France 2030: https://x.com/SGPI_avenir